Menu

Procédé de fabrication de sable de résine

- Home / Procédé de fabrication de sable de résine

Les moules sont généralement fabriqués en métal ou en bois pour garantir leur solidité et leur stabilité. Un revêtement de résine spécial est appliqué à l'intérieur du moule, puis le sable de résine est coulé dans le moule à l'aide d'une sableuse, puis compacté pour former un moule en sable solide. Le métal ou l'alliage liquide est versé dans le moule en sable et maintenu à chaud pendant 7 à 48 heures, après quoi la pièce moulée peut être retirée.

Le prix du moule est relativement bon marché, adapté à la production de grandes pièces moulées et les exigences de précision ne sont pas des produits stricts.

Avantages : Le moule en sable a une résistance élevée, convient aux pièces moulées de formes complexes, offre une grande précision dimensionnelle des pièces moulées et présente de faibles coûts de moulage.

Inconvénient : Ne convient pas aux petits lots et aux petites pièces.

Mélangeur de sable – Fabrication de coquillages de sable

Sable de résine – inspection de la coque

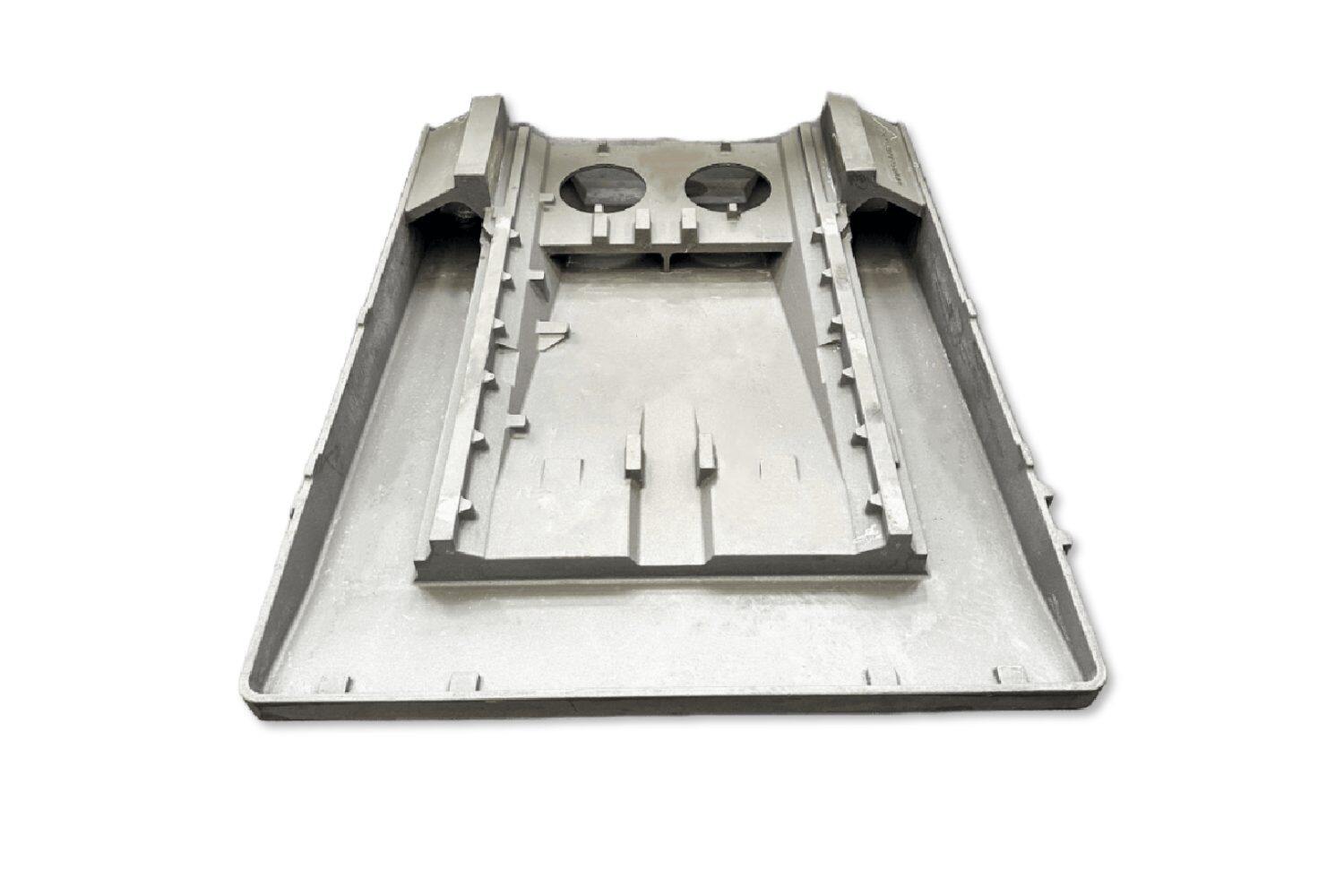

Centre d'usinage – Base

Poids : 570 kg Matériau : HT300

Machines-outils CNC – Base

Poids : 3258 kg Matériau : HT300

Shanghai keboer Casting Group Co., LTD