Menu

品質とサービス

- Home / 品質とサービス

当社では高硬度ねずみ鋳鉄を使用し、高精度のマシニングセンターで金型を加工することで、製品の精度誤差は0.5MM以内、金型は10万回以上の使用に耐えます。高精度・軽量の製品の製造に適しています。

鋳造用の砂殻を作るために、鋳造機で200メッシュの砂を鋳型に吹き付けます。鋳造後は7~12時間保温する必要があります。

利点: 粗鋳物は精度が高く、加工代が小さく、迅速に大量生産できます。

デメリット: 金型が高価であり、大規模鋳造や小ロット鋳造には適していません。

スペクトル検出

テスト回数: 1回

保証期間:1年間

引張試験

材質:QT400-15

結果:QT400-18.5

サイズ検査

製品:機械ベース。

結果:合格。

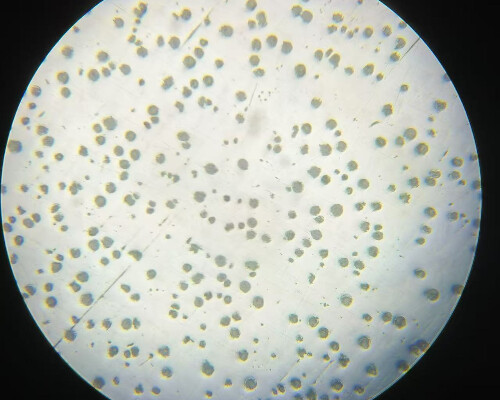

欠陥検出

製品:カップリング。

結果: 気孔なし。

当社のねずみ鋳鉄とダクタイル鋳鉄は、内部の気孔問題と鋳造安定性を完全に解決し、高品質の原材料を使用し、原材料をテストしてから他の合金材料を追加することで、製品の優位性を極め、有名な機械会社に認められています。

Shanghai keboer Casting Group Co., LTD