Menu

Qualität und Service

- Home / Qualität und Service

Wir verwenden hochharten Grauguss zur Herstellung von Formen und verwenden hochpräzise Bearbeitungszentren zur Bearbeitung von Formen. Dadurch kann sichergestellt werden, dass der Genauigkeitsfehler des Produkts 0,5 mm beträgt und die Form mehr als 100.000 Mal verwendet werden kann. Geeignet für die Herstellung von Produkten mit hoher Präzision und geringem Gewicht.

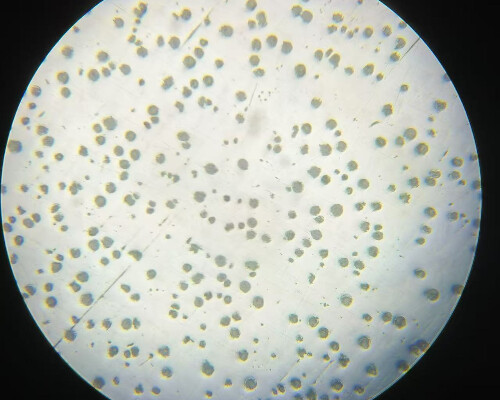

Mit der Formmaschine wird Sand mit einer Körnung von 200 in die Form gesprüht, um die Sandschale für den Guss herzustellen, die nach dem Guss 7–12 Stunden lang warm gehalten werden muss.

Vorteile: Die Rohgussteile weisen eine hohe Präzision und geringe Bearbeitungszugabe auf und können schnell in Massenproduktion hergestellt werden.

Nachteil: Die Formen sind teuer und eignen sich nicht für Großguss oder Kleinserienguss.

Spektrale Detektion

Anzahl der Tests: Einmal

Lagerdauer: Ein Jahr

Zugversuch

Material: QT400-15

Ergebnis: QT400-18.5

Größenprüfung

Produkte: Maschinenbasis.

Ergebnisse: qualifiziert.

Fehlererkennung

Produkte: Kupplungen.

Ergebnisse: Keine Stomata.

Unsere Grauguss- und Sphärogussteile lösen das Problem der inneren Porosität und der Gussstabilität vollständig. Durch die Verwendung hochwertiger Rohstoffe werden die Rohstoffe getestet und anschließend andere Legierungsmaterialien hinzugefügt. Der Produktvorteil ist extrem und wir haben die Anerkennung der namhaften Maschinenbauunternehmen erhalten.

Shanghai keboer Casting Group Co., LTD